Welcome to my wooden ship model blog, which will start with the Mayflower, my 4th wooden ship after The Black Prince, The Spray and, most recently, La Rose. I've also started working on the Bluenose as well, so I will probably be switching back and forth between them in this blog.

I'm about a week into the build, and have been tracking my progress so far in Word, so this first entry will be fairly long as I catch up.

August 1, 2013 (Thursday)

Ordered kit from Model Expo (on sale for $140 US, including free paint set).

August 6, 2013 (Tuesday)

Kit arrived.

Still building La Rose model, so will be a while before I will start.

Kit arrived.

Still building La Rose model, so will be a while before I will start.

August 23, 2013 (Friday)

Completed La Rose.

Cut the bulkhead former (aka false keel) out of the laser cut sheet.

Practice run at tapering the stern between the bearding line and the rabbet (yes, rabbet, not rabbit); this is intended to take the planking so they run smoothly at the edges. This is the first time doing this, as the previous kits I’ve done were all old and didn’t include this step. A lot of spots on the web said to do this with a small chisel – I’ve got the tools, but found it easier to use a file to get the taper.

The final version on the false keel. I hope I’ve got the angle and final keel thickness correct (2.4 mm, which is what the instructions say).

Pending the rabbet strip to the bottom of the false keel - again, this the first time in a long time that I’ve tried bending wood. My prior attempts on other ships were never really successful, so I had ended up cutting strips into shorter length and sanding the curves where needed.

I soaked the length to be bended in hot water for 10-15 minutes, then used an electric plank bender (a small tool with a heated end you run along the wet wood) to curve it into shape. Once I had the shape I needed, I temporarily attached it to the false keel and held it in place with elastics and clamps while it dried so it would retain its shape.

After it had dried (a couple hours), I attached it permanently using mostly wood glue along its length, with tiny drops of CA glue (cyanoacrylate – like superglue) at key points for a stronger bond. This was also held in place with elastics and clamps while it dried.

The final version, with the additional short strip attached to the stern post. This area was also filed down to retain the angle of the taper.

The next step was to test fit the 14 bulkheads to the false keel to ensure they all fit before gluing them in place (they go where the etched lines are on the false keel). Unfortunately, there was a problem with the laser cut pieces as the gaps on the bulkheads and the false keel were not quite wide enough, so I’ve started to widen them slightly using a file.

I finished up the first 7, starting from the bow, and they all now fit, but tightly. With those 7 attached, there is a marked warp to the false keel, so I’ll need to widen the gaps a bit more to minimize the warp. I may also need to use some filler blocks (like mentioned by other modellers - little blocks of wood which go between the bulkheads which helps straighten the keel by forcing the bulkheads on one side to spread apart slightly) to force it straight.

Filler blocks in between the bulkheads:

August 25, 2013 (Sunday)

Finished widening all of the bulkheads. Dry fitted them all in place, and added the kit supplied filler blocks, but there is still a fair bit of warp all along the keel with everything dry fitted in place, so will definitely need to use additional filler blocks.

Was able to remove all but 2 of the bulkheads (they are snug together, and too tight for me to get out with risking the keel snapping – Pieces 4 and 4b); they are tight enough that they should be okay without gluing (the others will all be glued).

I need to get the temporary base built before I proceed – it’ll just be a board with a groove cut in it to fit the keel so it will stand upright and remain straight while I glue the bulkheads in place and add the filler blocks.

August 27, 2013 (Tuesday)

Did some additional widening all of the bulkheads, and they now seem to fit better. There is still a bit of a warp in the keel, but not as bad as it was – I should be able to fix it up with just a couple additional filler blocks.

Or maybe not... the extra filler blocks did straighten out the keel, but it threw the bulkheads out of whack so that I wouldn’t be able to smoothly fix the planking later. I then finally managed to remove those 2 bulkheads I was having problems with, and, with no bulkheads attached, the keel is once again straight (I will probably put some weight on it tonight to make sure it retains its flatness). Looks like I’ll need to do more filing to try to make those 2 fit in place a bit easier so they don’t throw everything off again. From the looks of it, it is going to take a fair bit of filing… I really hope the rest of the kit goes smoother than this… if none of the pieces fit like they’re supposed to, this could be a much more difficult build than I anticipated…

On the plus side, I did get the groove cut in the temporary baseboard… on the negative side, there is not a lot of extra keel at the bottom of the ship to fit in the groove…

August 29, 2013 (Thursday)

Even more widening to all of the bulkheads last night and tonight… They all seem to now fit nicely and the keel is fairly straight with just the kit supplied filler blocks. Next step is the glue everything in place, but that’s for tomorrow

August 30, 2013 (Friday)

Bulkheads and filler blocks all glued in place. It was close to straight, but I had to add a few additional filler blocks to get it closer (and still keep the bulkheads aligned)… I still don’t think it’s 100% straight, but it should be close enough so the planking will pull it the rest of the way once I start that phase (still a ways down the road).

Even more widening to all of the bulkheads last night and tonight… They all seem to now fit nicely and the keel is fairly straight with just the kit supplied filler blocks. Next step is the glue everything in place, but that’s for tomorrow

August 30, 2013 (Friday)

Bulkheads and filler blocks all glued in place. It was close to straight, but I had to add a few additional filler blocks to get it closer (and still keep the bulkheads aligned)… I still don’t think it’s 100% straight, but it should be close enough so the planking will pull it the rest of the way once I start that phase (still a ways down the road).

Quite a noticeable warp to the keel with everything in place…

With the bulkheads in place, I moved on to add the deck of the beakhead (for the bow of the ship), as well as the stern frames for the stern.

The beakhead

The stern frames

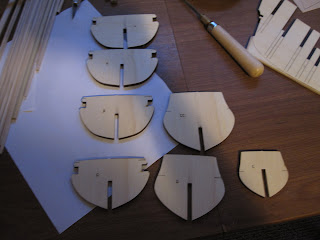

After gluing them on, I cut out the laser-cut stern pieces, including the windows for the middle piece (the “windows” in the bottom piece are not supposed to be cut out).

When dry-fitting these to the stern, I realized I had not pushed the last bulkhead far enough down in its slot, so the two outer stern pieces are slightly higher than the false keel, so I’ll need to sand things down a bit before I can attach the deck later. Plus the top stern piece is slightly above the deck line as well. Good thing I bought a file set… I have a feeling it’s going to get a lot of use on this build…

Oops…

The stern pieces all glued in place. The clamps in this photo are keeping elastics from sliding up the bulkheads… the elastics are holding a thin plank in place while the glue dries - I went too far down with one of the bulkheads…

With the stern pieces in place, I moved to gluing on the 2 false cannon strips (1 per side, using CA) – these are so if I leave the gun ports open you don’t see the bulkheads.

Next up was priming and painting the cannon strips, as well as a spot for an eyebolt in the port side filler blocks. These were all painted Iron Cannon Black (more of a dark grey than a true black) in 3 coats (plus the initial primer coat).

With everything painted and dried, I cut and soaked 4 3/32” x 3/32” for about 20 minutes, then attached them to the upper and lower gun port slits with CA, holding them in place while the glue dried so they would retain their shape.

Next up is cutting and shaping the side frames for the 8 cannon ports (so 16 ¼” pieces with an angle on the top and bottom so they fit smoothly between the upper and lower port frame), then drilling a small hole for the eyebolt and attaching it. Once that is done, it will be time to start fairing the hull in preparation for the first layer of planking…

The stern frames

After gluing them on, I cut out the laser-cut stern pieces, including the windows for the middle piece (the “windows” in the bottom piece are not supposed to be cut out).

When dry-fitting these to the stern, I realized I had not pushed the last bulkhead far enough down in its slot, so the two outer stern pieces are slightly higher than the false keel, so I’ll need to sand things down a bit before I can attach the deck later. Plus the top stern piece is slightly above the deck line as well. Good thing I bought a file set… I have a feeling it’s going to get a lot of use on this build…

Oops…

The stern pieces all glued in place. The clamps in this photo are keeping elastics from sliding up the bulkheads… the elastics are holding a thin plank in place while the glue dries - I went too far down with one of the bulkheads…

With the stern pieces in place, I moved to gluing on the 2 false cannon strips (1 per side, using CA) – these are so if I leave the gun ports open you don’t see the bulkheads.

Next up was priming and painting the cannon strips, as well as a spot for an eyebolt in the port side filler blocks. These were all painted Iron Cannon Black (more of a dark grey than a true black) in 3 coats (plus the initial primer coat).

In between coats, I created the eyebolt by wrapping a short length of 28 gauge brass wire around a 4mm dowel and then twisting the ends together. It actually turned out quite well! Since I used brass wire, I’ll need to paint it black after I attach it (or see if I have some black wire somewhere I can use to make another one – it was quick and easy).

Next up is cutting and shaping the side frames for the 8 cannon ports (so 16 ¼” pieces with an angle on the top and bottom so they fit smoothly between the upper and lower port frame), then drilling a small hole for the eyebolt and attaching it. Once that is done, it will be time to start fairing the hull in preparation for the first layer of planking…

Cannon ports are all framed, and the eyebolt attached (I cheated and, instead of drilling, simply used an awl to create the hole for the eyebolt, which worked just as well, if not better). Tomorrow I’ll start on fairing the hull, which will probably take a few days to get it where it needs to be so the planking will run smoothly along it without any buckles. This is one of the most important steps, as it will determine the overall smooth look of the model’s finished hull.

No comments:

Post a Comment